|

|

| Home | About Us | Product | Know How | Contact Us | |||||||||||||||||||||

|

|||||||||||||||||||||

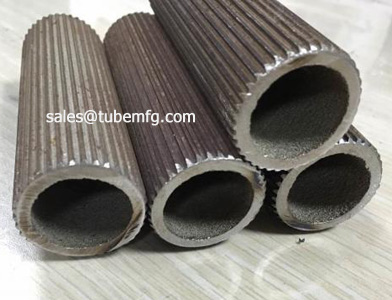

High Flux Tubes Outside Sintered Porous Coating |

|||||||||||||||||||||

|

|||||||||||||||||||||

High flux tubes with outside sintered porous coating is one type of sintered high flux tubes. High flux tubes can be classified into three types: Sintered high flux tube is the most expensive for its complex processing method and high efficiency among them. High flux tubes can reduce the steam demand. It can also improve the heat transfer capability. In the large heat transfer system, demands from small temperature differences, the number of reboilers needed is very big. The usage of high flux tubes can reduce 3/4 the amount of reboilers, and temperature difference ΔT asks for only 5 ℃. Using high flux tubes to replace traditional bare tubes can eliminate heat transfer bottlenecks, meet the needs of larger heat load, and significantly increase production. At the same time, under the condition of keeping the same efficiency, it can reduce the cost. Material and dimensions of our high flux tubes Material: Under normal condition, the middle of high flux tubes are enhanced section. Both ends are smooth. It is easy to wear tubes and easy for expansion joints. Applications of high flux tubes industry |

|||||||||||||||||||||

|

|||||||||||||||||||||

| Home | About Us | Product | Know How | Contact Us | |||||||||||||||||||||